Discarded electronics are piling up fast, pushing researchers to explore creative ways to reduce the resulting trash, known as e-waste. Now one team has crafted a water-activated disposable battery made of paper and other sustainable materials.

The wires, screens and batteries that make up our devices—not to mention the plastic, metal and other materials that encase them—are filling up landfills with hazardous debris. Some e-waste is relatively large: old flip phones, air conditioners and radios, to name just a few common items. Other e-waste is more insidious, such as electronic single-use medical diagnostic kits, environmental sensors and smart labels that contain disposable batteries and other equipment.

“It’s these small batteries that are big problems,” says Dele Ogunseitan, a public health professor at the University of California, Irvine, and a green technology researcher and adviser for major technology companies, who was not involved in the development of the paper battery. “Nobody really pays attention to where they end up.”

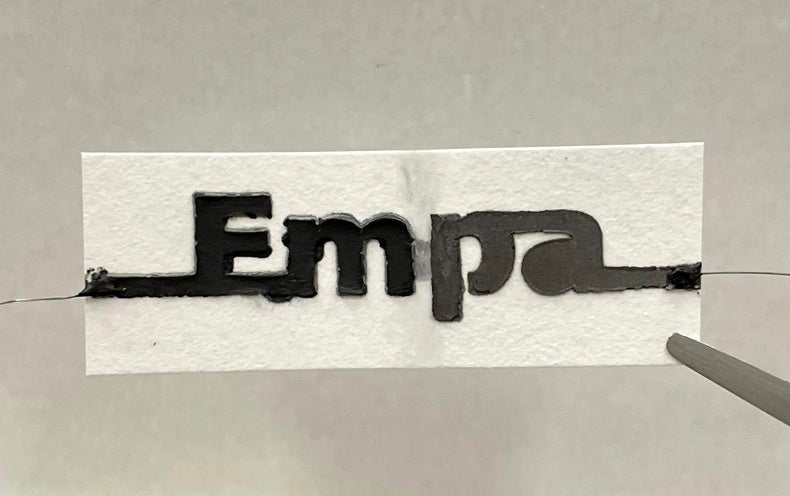

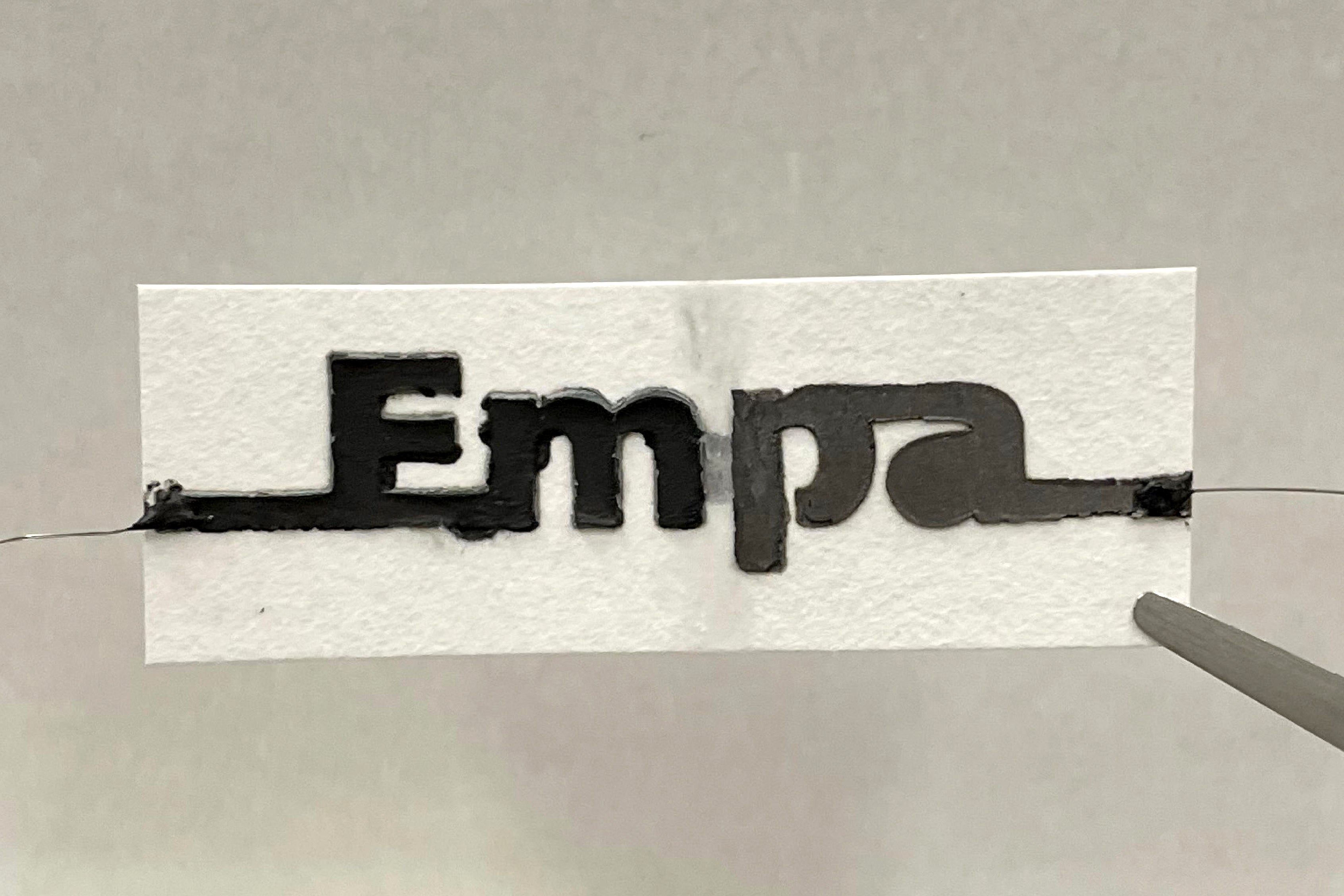

Researchers at the Cellulose & Wood Materials Laboratory at the Swiss Federal Laboratories for Materials Science and Technology (Empa) are working to address this overlooked problem. This week they published a paper in Scientific Reports describing a new water-activated paper battery they developed out of environmentally friendly materials. Such a device could eventually present a sustainable alternative to the more harmful batteries that are common in low-power devices.

The new paper battery has the same key components as standard batteries but packages them differently. Like a typical chemical battery, it has a positively charged side called a cathode, a negatively charged side called an anode and a conductive material called an electrolyte between the two. A traditional battery’s components are encased in plastic and metal; in the new battery, the anode and cathode are inks printed onto the front and back of a piece of paper. That paper is infused with salt, which dissolves when the paper is dampened with water. The resulting saltwater solution acts as the electrolyte.

Sustainable materials were a prerequisite for the researchers, who only considered nontoxic and abundant ingredients to create their device. “We were fairly confident that we would have something that would work in the end, but developing these materials and ink systems is far from trivial,” says Gustav Nyström, head of the Cellulose & Wood Materials Laboratory and senior author of the study. After trying hundreds of formulations for the different components, the scientists settled on a graphite ink to make the cathode, a zinc ink for the anode and salt-infused paper to create the electrolyte. When the paper is dry, the battery is shelf-stable. Add just a couple of drops of water, however, and the engrained salt dissolves, allowing electrons to flow. After the paper is moistened, it takes about 20 seconds for the battery to activate. At that point, it produces a stable 1.2 volts of electricity until the paper dries out. (For comparison, an AA battery provides 1.5 volts.) When the researchers rewet the paper, the battery produced 0.5 volt for more than an hour.

Although the researchers demonstrated that their battery could power an alarm clock, disposable paper batteries are unlikely to replace standard AAs on store shelves. Instead Nyström envisions a future where these batteries are embedded in diagnostic tests and environmental sensors, ideally with other sustainable components such as screens and packaging. That future may not be so far off.

It is hard to predict a time line for manufacturing such items at scale, but Nyström says he is in contact with potential industry partners and believes these batteries could make their way into products within the next two to five years. “The performance that you see on this device, I think, is sufficient for a lot of these applications already,” he says. It is mostly a matter of scaling up production and integrating the batteries into systems such as diagnostic tests and environmental sensors.

Crucially, Nyström says his team created the battery without compromising on sustainability criteria. “This is work that really starts with the development of sustainable materials,” he explains. From there, he says, “I think we were able to create something that is quite useful.”